- Custom Weld Automation Systems: We provide new systems that are tailored to client specifications, ensuring alignment with production goals.

- Optimisation Services: JTR helps improve the performance of existing automation setups, ensuring they operate at peak efficiency.

- Maintenance and Support: Our company offers routine maintenance, troubleshooting, and repair services to ensure the longevity and reliability of automation systems.

- Diverse Industry Support: Our expertise spans various industries, providing solutions for complex and high-demand applications.

-

-

Features of Conventional Welding Rotators

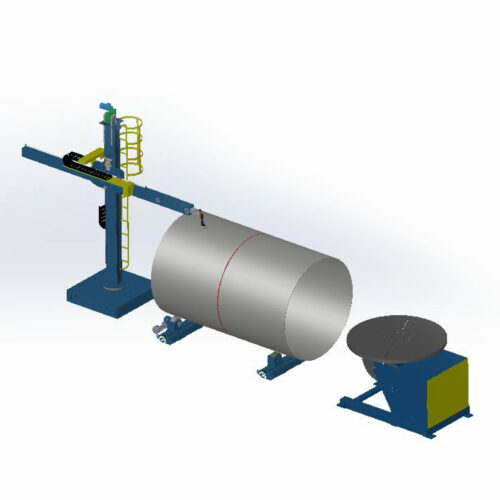

Features of Conventional Welding Rotators- Independent Drive and Idler Units: Separate units for driving and supporting the workpiece, allowing flexibility for handling vessels of varying lengths and weights. Rotator wheels provide secure support and smooth rotation.

- Adjustable Wheels: The base frame features adjustable wheels, accommodating different vessel diameters without requiring additional tools.

- Variable Speed Control: Equipped with speed adjustment capabilities, often through a pendant or remote control, enabling precise control over the rotation speed.

- Robust Build: Constructed from durable materials to handle heavy loads and harsh industrial environments.

- Safety Features: Anti-slip mechanisms and overload protection ensure safe operation.

- Customizable Options: Available in various capacities and configurations to suit specific industry needs, including additional features like digital displays or automated systems.

-

Transform your operations with DOBOT's versatile robotic arms, now available through JTR Automation Limited. DOBOT Robotics offers a wide range of cost-effective, scalable robotic solutions designed for various applications, from industrial automation to education and research. Known for their intuitive programming and user-friendly setup, DOBOT systems make robotics accessible to businesses of all sizes. DOBOT's robotic arms deliver precision, reliability, and efficiency. Features include:

Transform your operations with DOBOT's versatile robotic arms, now available through JTR Automation Limited. DOBOT Robotics offers a wide range of cost-effective, scalable robotic solutions designed for various applications, from industrial automation to education and research. Known for their intuitive programming and user-friendly setup, DOBOT systems make robotics accessible to businesses of all sizes. DOBOT's robotic arms deliver precision, reliability, and efficiency. Features include:- Compact, lightweight designs for easy deployment.

- Compatibility with multiple programming languages for seamless integration.

- Advanced functionalities, including vision systems and AI capabilities.

-

- 360-Degree Rotation: Facilitates continuous and smooth rotation of workpieces for seamless welding, reducing downtime for repositioning.

- Heavy-Duty Construction: Built to handle substantial loads, with capacities ranging from a few hundred kilograms to several tons.

- Variable Speed Control: Enables precise adjustment of rotation speed to match specific welding requirements.

- Low-Profile Design: Easy integration into workshops and welding setups without the need for complex installation.

- Remote or Pendant Controls: Enhances usability and operator safety by providing control from a distance.

- Customizable Platforms: Can accommodate workpieces of various shapes and sizes, including irregular and asymmetrical components.

-

Melt Tools provides advanced welding vision solutions that improve the quality and precision of welding processes. Their MeltView™ system includes a range of cameras, such as the PIXI, DART2, and APEX3, which are designed for various applications including real-time weld viewing, high-speed imaging, and AI-powered defect detection. These systems are tailored to industries like aerospace, automotive, and manufacturing, ensuring reliable results and operational efficiency. These solutions help ensure weld quality, reduce defects, and enhance safety in automated and manual welding environments. The MeltView DART2 welding camera builds on the tradition of our flagship camera with smaller size and 3x higher resolution. The MeltView DART2 is employed to monitor open-arc welding applications at working distances between 100-400 mm (4-16″) at temperatures up to 300°C (570°F). Features of DART 2

Melt Tools provides advanced welding vision solutions that improve the quality and precision of welding processes. Their MeltView™ system includes a range of cameras, such as the PIXI, DART2, and APEX3, which are designed for various applications including real-time weld viewing, high-speed imaging, and AI-powered defect detection. These systems are tailored to industries like aerospace, automotive, and manufacturing, ensuring reliable results and operational efficiency. These solutions help ensure weld quality, reduce defects, and enhance safety in automated and manual welding environments. The MeltView DART2 welding camera builds on the tradition of our flagship camera with smaller size and 3x higher resolution. The MeltView DART2 is employed to monitor open-arc welding applications at working distances between 100-400 mm (4-16″) at temperatures up to 300°C (570°F). Features of DART 2- Rich monochrome or colour image of all open arc welding processes including GMAW, FCAW, MCAW, GTAW, PAW

- Automatic switching between arc-on and arc-off modes

- External focus adjustment between 100 mm (4") and 400 mm (16")

- Integrated cooling, protection, and lighting

- Camera displays directly to monitor, no computer or software required

- Adjustable dual crosshairs

- Requires a MeltView camera controller

- Optional frame grabber or DVR for recording video

- Standard X-coded or F-style cable; other transmission systems available (wireless, fibre, dual cable)

-

- 360-Degree Rotation: Allows continuous rotation of the workpiece for seamless welding, improving consistency.

- Tilt Functionality: Enables the workpiece to be tilted to an optimal angle for ergonomic and efficient welding.

- Adjustable Speed Control: Ensures precise control over the rotation speed, essential for high-quality welds.

- Heavy-Duty Construction: Designed to handle large and heavy workpieces, providing stability during welding.

- Fixture Compatibility: Customizable chucks or clamps to secure workpieces of various shapes and sizes.

- Automation Integration: Can be integrated with robotic systems for fully automated welding processes.

- Remote Control Operation: Enhances safety and convenience by allowing operators to control the positioner from a distance.